| Hydrant System | ||||||||||||

Being one of the oldest but yet the most effective and common fire fighting solution, a well designed and a well laid out Hydrant System forms the backbone of the entire fire fighting system. It comprises of heavy duty above & underground piping with accessories. External and Fire Escape Hydrant valves are provided at every strategic location. A fire hydrant is a pipe that allows water to flow from a water main with the control of a valve in order to put out a fire.

|

||||||||||||

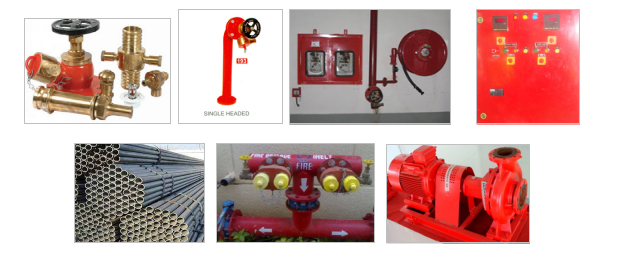

| Components of the System | ||||||||||||

|

||||||||||||

| • Fire Fighting Pumps & Accessories | ||||||||||||

| • Piping | ||||||||||||

| • Panels | ||||||||||||

| • Landing Valves | ||||||||||||

| • Hoses | ||||||||||||

| • Couplings | ||||||||||||

| • Hose Reel | ||||||||||||

| • Branch Pipes & Nozzles | ||||||||||||

| • Fire Brigade Connections | ||||||||||||

| • Wiring & Instrumentations | ||||||||||||

| • Maintenance Valves | ||||||||||||

| Operational Information | ||||||||||||

| Hydrant System | ||||||||||||

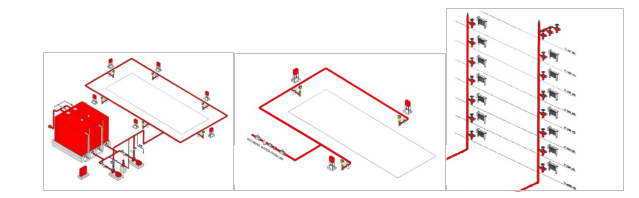

Fire hydrant installation consists of a system of pipe work connected directly to the water supply main to provide water to each and every hydrant outlet and is intended to provide water for the firemen to fight a fire. The water is discharged into the fire engine form which it is then pumped and sprayed over fire. Where the water supply is not reliable or inadequate, hydrant pumps should be provided to pressurize the fire mains.

|

||||||||||||

|

||||||||||||

The Fire Pump Station comprises of the Jockey Pump, Electric Driven Pump and Stand-by Diesel driven Pump. The pump operation is automatic through pressure switch contacts based on header Pressure in the hydrant network. The delivery of the jockey ump and main pump is connected to the common delivery header.

|

||||||||||||

|

||||||||||||

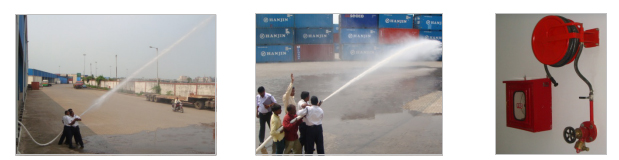

| A fire-fighter connects a fire hose to the fire hydrant and releases a valve to get water from the water main. Most fire hydrants are designed to allow not less than 250 gallons (950 litres) of water to flow through the hydrant per minute. | ||||||||||||