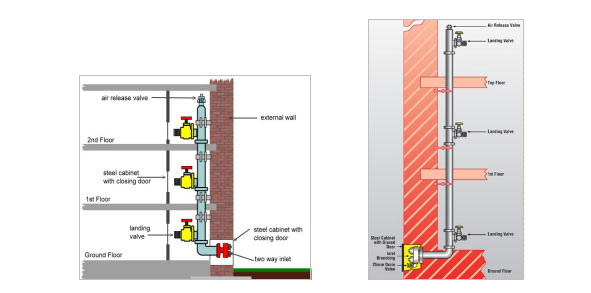

A typical building normally has two or more shafts,

which travel from the lowest level of the building

to its terrace. Such shafts are normally used to

carry the piping for the wet-riser systems. Hydrant

outlets are provided on every floor so that the

entire floor area of the building is adequately

covered. Outlets are provided in the form of

double-outlet landing valves apart from a canvas

hose for the use of fire-fighting personnel in the

event of fire.

All wet-riser pipes remain charged with water at systems pressure. The opening of a hydrant landing valve or hose reel on any floor reduces the pressure in the pipeline and starts the hydrant pump. Pump-sets of suitable capacity are provided for this purpose. Because of the static pressure differential caused by the change in floor height, a multi-stage pump is employed so that different tapping can be taken from the output of the pump. Each of these tapping can be used to serve more than one floor. Pumps-sets should be fed with reliable electric supply from a separate feeder and it is therefore also desirable to have a stand-by diesel pump.

Guidelines and approval for Hydrant

System are available from various national and

international organizations like: NBC, NFPA, TAC,

IS, FM and Local Fire Authorities.

Components of the System

• Fire Fighting Pumps & Accessories

• Piping

• Panels

• Landing Valves

• Hoses

• Couplings

• Hose Reel

• Branch Pipes & Nozzles

• Fire Brigade Connections

• Wiring & Instrumentations

• Maintenance Valves